Understanding Torque Converters: A Comprehensive Manual

What is a Torque Converter?

A torque converter is a crucial component in automatic transmissions, serving to convert the engine’s rotational power into usable torque for the wheels. It acts as a bridge between the engine and the transmission, allowing for smooth acceleration and efficient power transfer.

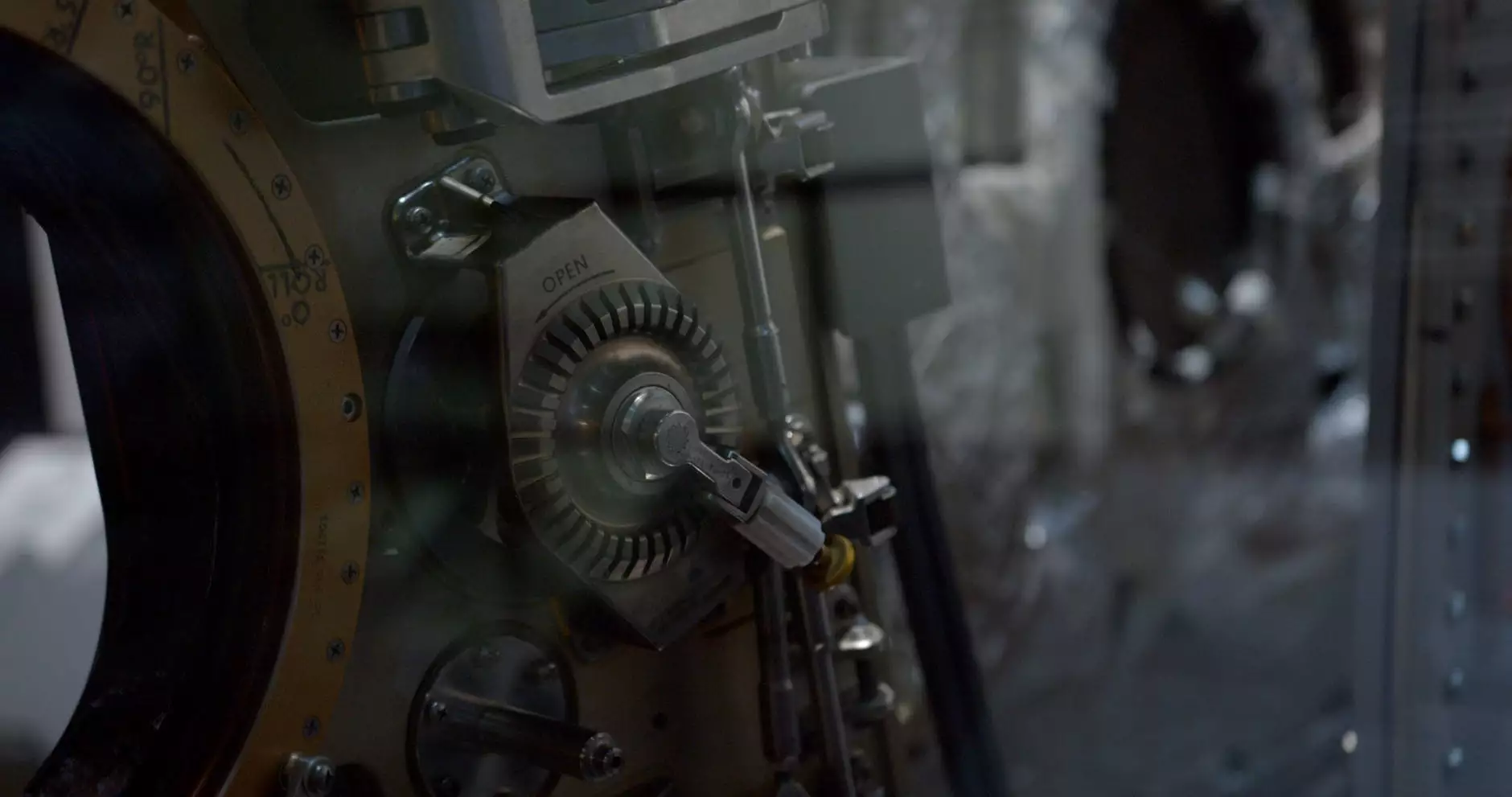

The Anatomy of a Torque Converter

To fully appreciate how a torque converter manual functions, we must examine its primary components:

- Impeller: The impeller is connected to the engine and spins to generate hydraulic pressure.

- Runner: The runner, also known as the turbine, receives fluid from the impeller and spins the transmission’s input shaft.

- Stator: Positioned between the impeller and runner, the stator redirects fluid to improve efficiency.

- Fluid Coupling: This serves as the fluid medium, critical for transferring energy between the impeller and runner.

How Does a Torque Converter Work?

The operation of a torque converter is often described in several stages. When the engine runs, it spins the impeller, which pushes transmission fluid towards the turbine (runner). This kinetic energy transfer allows the vehicle to move without stalling the engine while idling.

Moreover, the torque converter also utilizes a feature known as the lock-up clutch. This mechanism engages at higher speeds to eliminate slip by directly coupling the engine to the transmission, enhancing fuel efficiency.

Types of Torque Converters

There are various types of torque converters suited for different applications. The most common include:

- Single-stage Torque Converters: These are standard in most vehicles, offering a balance of performance and efficiency.

- Multi-stage Torque Converters: Designed for high-performance applications, they provide enhanced torque multiplication and lower slip.

- Variable Geometry Torque Converters: These adjust their internal geometry for optimal performance under varying load conditions.

Benefits of Using a Torque Converter

Integrating a torque converter into an automatic transmission system offers numerous benefits:

- Smooth Operation: Provides seamless gear shifts and a more comfortable driving experience.

- Enhanced Acceleration: Greater torque multiplication allows for quicker acceleration off the line.

- Improved Fuel Efficiency: The lock-up clutch minimizes engine strain, allowing for better gas mileage.

Common Issues and Solutions

Understanding potential issues with torque converters is essential for preventing costly repairs. Some common problems include:

1. Slipping Torque Converter

This occurs when the engine revs higher than the vehicle's speed. It can often be attributed to low fluid levels, worn clutch plates, or hydraulic issues.

2. Overheating

Excessive heat can damage internal components. Regular maintenance, including fluid checks, can help mitigate this risk.

3. Shuddering During Acceleration

Shuddering often indicates worn or damaged parts within the torque converter. It may necessitate a complete assessment of the converter and possibly a replacement.

Maintaining Your Torque Converter

Regular maintenance is vital to ensure the longevity and performance of your torque converter. Here are some essential tips:

- Check Transmission Fluid Regularly: Maintain proper fluid levels and use the manufacturer-recommended fluid type.

- Flush the Transmission: At regular intervals, flush the transmission fluid to remove debris and contaminants.

- Inspect for Leaks: Look for signs of fluid leaking under the vehicle and address any leaks immediately.

Choosing the Right Torque Converter

Selecting the appropriate torque converter involves understanding your vehicle's specifications and expected performance outcomes. Consider the following factors:

- Vehicle Type: Different vehicles require different torque converter types based on their weight and engine power.

- Power Output: Ensure the torque converter can handle your engine’s horsepower and torque ratings.

- Driving Style: Consider whether your driving style is more performance-oriented or focused on fuel efficiency.

Conclusion

The torque converter manual serves as a fundamental resource for understanding the operation, maintenance, and selection of torque converters within the automotive industry. By familiarizing yourself with this essential component, you empower yourself to enhance vehicle performance, ensure smoother rides, and make informed purchasing decisions that can positively affect vehicle longevity.

If you’re interested in exploring more about automotive components, visit Shenghai Auto Parts for a wide array of products, expert advice, and comprehensive manuals tailored to your needs.

Frequently Asked Questions (FAQs)

1. What is the main purpose of a torque converter?

The primary purpose of a torque converter is to convert the engine's rotational energy into hydraulic energy and transfer it to the transmission.

2. How often should I change my torque converter fluid?

It’s recommended to check your torque converter fluid every 30,000 to 60,000 miles and change it as necessary based on manufacturer guidelines.

3. Can a failing torque converter cause poor fuel economy?

Yes, a failing torque converter can lead to increased engine load and slippage, resulting in poor fuel economy.

4. Are there torque converters designed for heavy-duty vehicles?

Yes, there are torque converters specifically designed for heavy-duty applications that provide increased durability and performance.

5. How can I recognize if my torque converter is failing?

Signs of a failing torque converter include slipping, overheating, shuddering, or unusual noises coming from the transmission.